|

Cycle speed maximum (with good CN mold) |

Forming adn cutting production cycle of up to 30 cycles/min. Single forming production cycle of up to 35 cycles/min. |

|

設備運轉大速度(在使用國內品質好的模具的情況下) |

成型沖切可以達到30周期每分鐘,單成型可達35周期每分鐘 |

|

Dry cycle speed |

50 cycles/min |

|

空機運行周期 |

50周期每分鐘 |

|

|

760x580mm |

|

大成型面積 |

|

|

Forming area minimum |

375x350mm |

|

小成型面積 |

|

|

Closing force (Forming/Cutting station) |

250KN/500KN |

|

閉合力(成型/沖切站) |

|

|

Height of formed part above or below film level |

150mm |

|

成型產品高度,正向/負向 |

|

|

Forming station Top / Bottom table movement |

170mm |

|

成型站上/下工作臺移動 |

|

|

Film thickness range (depending on film properties) 膜料 |

0.2-1.8mm |

|

厚度范圍(取決于膜料特性) |

1 Integrated forming, punching, stacking, and waste winding station, sheet stock treatment is more smooth, and energy consumption is less.

集成的成型、沖切、堆疊、廢料收卷工位,片料處理更順暢,能源消耗更低。

2 Forming and cutting station use firm cast iron structure, matched with roller bearing's crankshaft to guarantee perfect forming, cutting.

成型及裁切站使用牢固的鑄鐵結構,配用滾柱軸承的曲臂保證成型,裁切。

3 Forming station with independent servo-plug drive on upper table, gives you more flexible to adjust the process, gets the best products.

成型站上工作臺獨立伺服馬達驅動的輔助拉伸頭。可以讓您更靈活的調整生產工藝,得到好品質的產品。

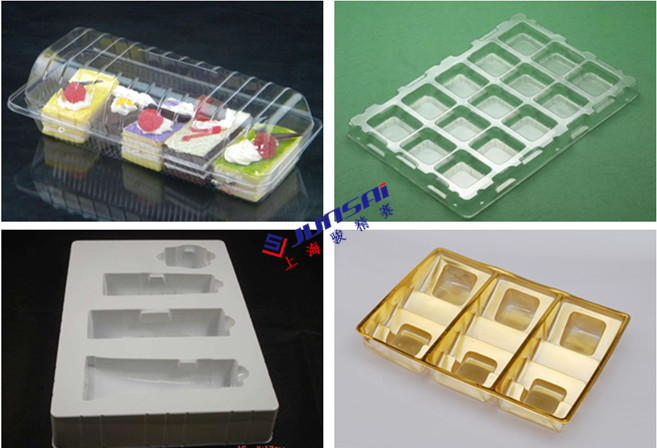

主要適用于PS、HIPS、PVC、PET、PP等塑料片材成型,生產各種盒、碟、托盤、碗、蓋等包裝制品。如:食品盒、蛋糕盒、快餐盒、糕點托盤、超市托盤、醫(yī)藥針劑托盤、口服液托盤.等

上海駿精賽自動化有限公司

上海駿精賽自動化有限公司